How to Build a “Superior Output” PU/PIR Sandwich Panel Production Line

Everyone’s looking for buildings that save energy, last longer, and meet today’s safety standards. This is why the market for PU/PIR sandwich panel production line is rapidly expanding. Sandwich panels offer strong insulation, long service life, and the efficiency modern construction needs.

- 1. Why The Market Is Expanding

- 2. What is the difference between a Basic PU/PIR Sandwich Panel Production Line and an Advanced One

- 3. The Anatomy of a Modern PU/PIR

- Sandwich Panel Production Line

- 4. Planning Your Sandwich Panel Production Line Strategy

- 5. Choosing Between PU and PIR Cores

- 6. Cost, ROI, and Efficiency Drivers

- 7. Best Practices for Operation & Maintenance

- 8. Why Choose Fineagles Advance Engineering

- Conclusion

If you want to invest in this field, you need a production line that works efficiently and reliably. This guide will help you make a solid and effective plan for your future-ready setup..

1. Why The Market Is Expanding

If you have been following this market, you probably noticed how fast demand for better building insulation is growing. Every year, projects require more materials that save energy and meet new safety standards. The sandwich panel market was valued at US$2,711.11 million in 2021 and is projected to reach US$4,256.62 million by 2028 (Source: Research and Markets).

What is driving this massive shift?

The momentum comes from four critical industry movements:

- The Cold-Chain Revolution: The need for precise temperature control, from pharmaceuticals to frozen food, is creating a massive demand for millions of square meters of sandwich panels.

- The Prefabrication Standard: Modern construction values speed and consistency. Builders are moving away from traditional on-site construction and relying entirely on the quality and rapid deployment of factory-made panels.

- Non-Negotiable Energy Efficiency: Stricter global building codes are not suggestions; they are mandates. This drives demand directly towards superior insulation materials, such as PU and PIR.

- The Fire Safety Priority: Global safety regulations are tightening. This naturally pushes manufacturers to adopt the excellent fire-resistant properties of PIR cores.

The message is clear: the investment window is open now. Securing your competitive position requires immediate action.

2. What is the difference between a Basic PU/PIR Sandwich Panel Production Line and an Advanced One

A highly-efficient PU/PIR sandwich panel production line is not just a collection of expensive equipment. It needs to operate as a single, highly refined manufacturing system. The goal is not just to produce panels, but to maximize quality output while reducing waste and eliminating operational headaches.

A high-performing line delivers on these four critical promises:

- Flawless, Consistent Quality: Quality assurance begins at the very start of the production line- with the decoiling of the metal sheets. Every single panel must feature perfect bonding and uniform foam density.

- Zero-Tolerance Waste: Raw materials are costly. Precise metering and cutting accuracy are essential. If you tolerate waste, you are losing profit on every shift.

- Agile Changeovers: Flexibility wins bids. Your line should be fast and flexible enough to switch between different panel types and thicknesses. It must also adapt quickly to changes in client orders or core formulations.

- Guaranteed Uptime: Predictable output is the metric that matters most. Robust mechanical engineering combined with centralized automation ensures that your line runs reliably 24/7, enabling you to meet aggressive deadlines.

- Fineagles’ continuous production systems embody these four principles: precision, uptime, zero waste, and rapid adaptability.

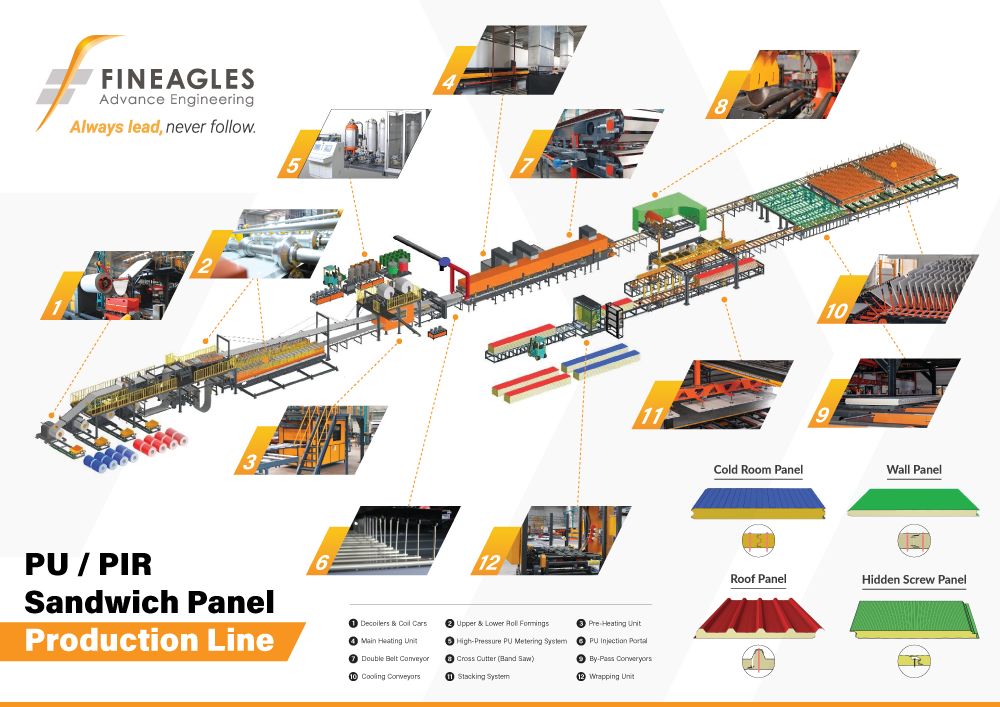

3. The Anatomy of a Modern PU/PIR

Sandwich Panel Production Line

A high-speed line integrates five specialized systems. When synchronized perfectly, these components turn industrial steel and bulk chemicals into high-value sandwich panels.

a. Coilcar and Decoilers

Production begins with the precise loading of steel coils. Fineagles’ Coil Car securely positions each coil onto the Decoiler, ensuring safe and efficient handling.

The Decoiler then unwinds the coil under controlled tension, delivering a smooth and consistent feed into the line. This coordinated system ensures stability, prevents material stress, and provides a reliable start to the entire production process.

b. The Roll Forming Unit

This is the foundation. This unit must precisely shape your metal facings (top and bottom sheets) to ensure structural integrity and dimensional accuracy.

They allow quick mold changes and ensure stable, precise, high-speed profiling. Importantly, your roll forming equipment must have the versatility to handle different materials, including steel and aluminum.

c. Foaming & Injection System (The Core)

This is the chemical heart of the process. It mixes and measures the Polyol, Isocyanate, additives, and blowing agent before injecting them onto the lower metal sheet. Fineagles’ mixing system maintains uniform foam density and reduces material waste, thereby helping to control costs and improve quality. To match different production needs, Fineagles provides both fixed and oscillating mixing heads.

d. The Double Belt Press (The Curing & Bonding)

The Double Belt Press is where the foam curing initiates. It applies controlled heat and pressure to complete the chemical reaction. This process lets the foam expand and bond firmly to the metal sheets.

The length of this press directly impacts your maximum line speed and panel thickness capabilities.

e. Cutting, Cooling & Stacking Section

The panel requires precision finishing. Automated band saw cross-cutters cut the panels according to the input size, synchronized perfectly with the line speed to ensure consistent quality. After cutting, the panels are transferred onto cooling conveyors, where they are allowed to stabilize and cool to the desired temperature before handling. Once cooled, the finished panels are conveyed to the vacuum stacker for automated stacking, minimizing manual intervention and ensuring efficient downstream processing.

f. Control & Automation (The Brain)

A modern line operates through a centralized PLC system, allowing the operator to control and monitor chemical ratios, temperature, pressure, and speed via HMI screens. Integrated with Fineagles’ smart control units, the system enables remote support and quick diagnostics, ensuring consistent, high-quality production with minimal operator input.

g. Wrapping & Packaging Section

After stacking, the panel bundles are transferred to the wrapping unit. Fineagles’ wrapping systems ensure uniform film sealing, protecting panels from dust, moisture, and handling damage.

4. Planning Your Sandwich Panel Production Line Strategy

Setting up a plant requires careful, detailed planning that extends beyond machinery selection.

When setting up your plant, consider the following strategic steps:

Define Product Range: Clearly specify the exact panel thickness range (e.g., 40mm to 200mm), and core type (PU/PIR/Mineral Wool) your line must handle. This dictates the design parameters of the roll former and the length of the press.

Determine Capacity: Establish your target output, panels per minute or daily square meter output. This decision drives the speed requirement for the entire line, especially the foaming unit’s output and the double belt press length.

Design Layout: Allocate sufficient, protected space for foaming, curing, product packaging, and safe chemical storage (polyol and isocyanate tanks, which require specialized fire suppression).

Plan Utilities: Specify the requirements for power (high-capacity electricity for the main heater unit of the press), robust ventilation (for chemical fumes), and a safe chemical storage/handling system compliant with all local environmental and safety regulations.

Choose Automation Level: Decide between a semi-automatic line (lower initial cost, higher labor) or a fully automatic line (higher cost, maximum efficiency and accuracy). For long-term ROI and consistent quality, high automation is the strategic choice.

Need guidance on plant planning? Fineagles provides expert consultancy for business planning, facility layout, and sales strategy. Contact Fineagles for a free consultation tailored to your production goals.

5. Choosing Between PU and PIR Cores

The core material is the heart of the panel’s performance. The choice between Polyurethane (PU) and Polyisocyanurate (PIR) is critical for meeting specific market needs.

| Feature | PU Panels | PIR Panels |

| Thermal Insulation | Excellent | Excellent (Slightly better λ value) |

| Fire Resistance | Good (B2/B3 ratings) | Superior (B-s1,d0 or similar high fire-rated performance) |

| Cost | Lower | Slightly higher |

| Ideal Use | Cold storage, simple roofs, and general industrial buildings | Industrial, pharmaceutical, fire-rated walls, and public buildings |

While PU offers lower initial material costs, the superior fire rating and potential insurance benefits often make PIR the more strategic long-term choice for specific projects.

Your line must be engineered to handle both formulations efficiently and without cross-contamination issues.

6. Cost, ROI, and Efficiency Drivers

Understanding the cost structure is key to running a profitable operation. It helps you control expenses and keep your ROI strong throughout the equipment’s lifetime.

Major Cost Factors:

- Machinery and Installation: The initial capital investment for the PU/PIR sandwich panel production line

- Chemicals: The recurring and largest operational cost (polyol, isocyanate, catalysts).

- Utilities and Labor: Energy consumption and all associated personnel costs, including operators, technicians, and support staff.

- Maintenance: Routine maintenance schedules.

How Efficiency Increases ROI:

- Precise Mixing Minimizes Waste: High-accuracy foaming systems prevent off-spec panels and eliminate expensive chemical overshoot.

- Automation Boosts Output: A fast, consistent line produces more square meters per shift than any semi-automatic setup, directly lowering your cost per square meter.

- Operational Control Reduces Downtime: Fineagles’ PLC systems continuously monitor temperature, pressure, and speed, ensuring stable operation and quick adjustments when needed.

- Energy-Efficient Curing Lowers Bills: Modern, highly insulated double belt presses are designed to minimize heat loss, significantly reducing the utility cost per finished panel.

7. Best Practices for Operation & Maintenance

You bought a high-performance machine, now treat it like one. Maintaining your PU/PIR sandwich panel production line in peak condition is non-negotiable for maximizing uptime and quality control.

To ensure long-term performance:

- Follow Maintenance Checklists: Implement strict daily, weekly, and monthly maintenance procedures for all mechanical, electrical, and hydraulic components. Never skip a routine check.

- Clean Foaming Heads Regularly: Chemical residues are corrosive and will rapidly compromise the accuracy of your foam distribution. The mixing head is the most sensitive and critical part of the entire line, and cleaning it thoroughly and often is essential.

- Monitor Chemical Ratios and Temperatures: Even small changes in the chemical mix or temperature can affect foam density and curing time. Check and calibrate your sensors and pumps regularly to keep quality stable.

- Stock vital spare parts: specifically for the metering unit, band saw blades, and primary control electronics. Production downtime caused by missing parts is the quickest way to halt operations.

- Train Operators Continuously: Invest in your team. Well-trained operators are the first line of defense against both mechanical failure and expensive quality defects.

8. Why Choose Fineagles Advance Engineering

Fineagles is a global manufacturer specializing in sandwich panel production lines for PU, PIR, and mineral wool panels. Our engineering focus is on reliability, precision, and efficiency, the three pillars of a high ROI.

In-house Production: We manufacture our key components, ensuring strict quality control from raw material to final assembly.

Custom Designs: We provide custom-tailored designs for client-specific needs

Integrated Automation: Our lines feature integrated automation and smart diagnostics that simplify operation and drastically reduce human error.

Worldwide Support: Fineagles provides comprehensive installation, operator training, and reliable global after-sales support.

Conclusion

Building a high-performance PU/PIR sandwich panel line is a major investment. It’s a strategic move that shapes your long-term position in the sandwich panel market. With Fineagles’ technology and engineering expertise, you can produce panels that meet today’s energy and safety standards while ensuring a solid return on your investment.

Contact Fineagles for a project consultation today and turn your manufacturing vision into a profitable reality.